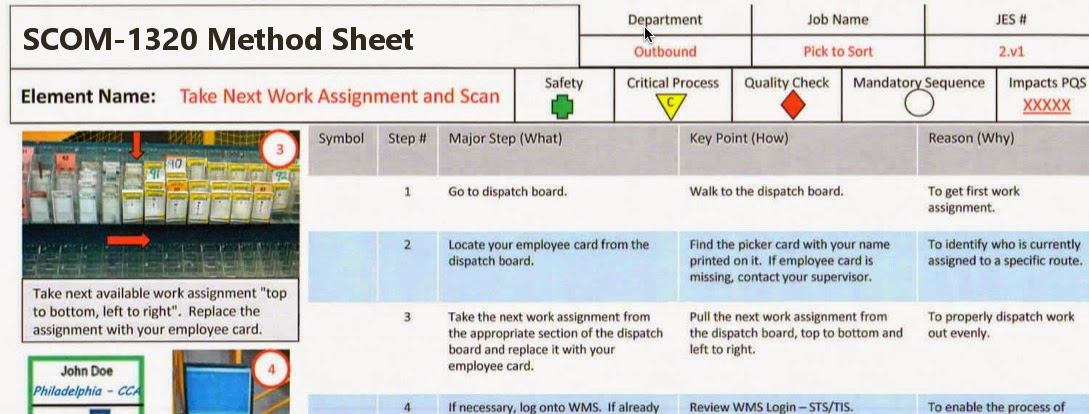

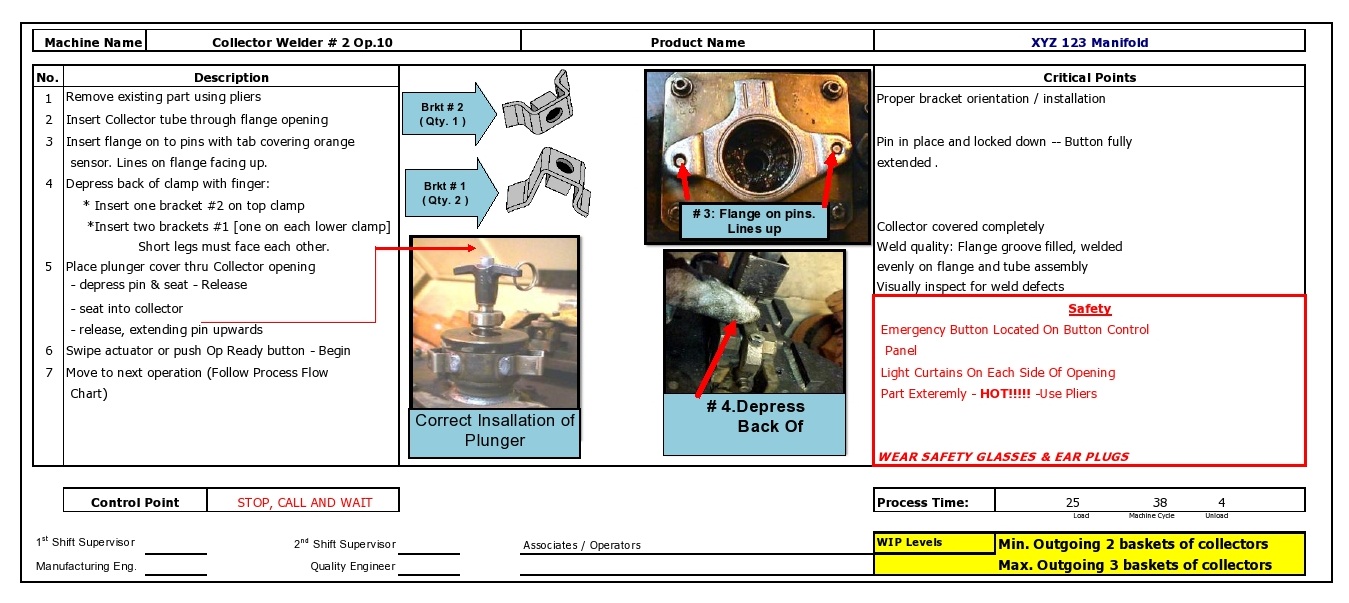

Skilled labor is hard to find, that is because the work operators do can be very complex. Whether it is assembling or running a machine, there is a great deal of technique involved. Each element of a process requires precision and speed, there is little time for trial and error. Method sheets are intended to be a clear instruction to assist operators in completing a task on time.

Unlike technical prints that do not show operators the sequence of actions, the purpose of method sheets are to capture the tribal knowledge that experience creates. These work instructions need to provide a clear understanding of technique, safety concerns, and quality expectations in a way that any operator could fill in for another.

When you begin to document your process, though engineers can be a great help, it is better to work directly with the operators that build the product. Casually watch what they do and occasionally ask them what they are doing. If the production line isn’t too busy, attempt to build the product yourself with the guidance of the operator - you will quickly learn that you do not possess the same skillset that they do! Note each task that is deemed difficult, or has a critical tolerance, and be sure to record the action needed to successfully complete.

When you begin to document your process, though engineers can be a great help, it is better to work directly with the operators that build the product. Casually watch what they do and occasionally ask them what they are doing. If the production line isn’t too busy, attempt to build the product yourself with the guidance of the operator - you will quickly learn that you do not possess the same skillset that they do! Note each task that is deemed difficult, or has a critical tolerance, and be sure to record the action needed to successfully complete.

Method sheets should include color photos as well as the bill of materials needed to build the product. It is a good idea to show the operators the photos you take in order to get their feedback. Unless you are using digital work instructions that have no content limit, you will need to be sure to size your photos in a way that maximize the content without crowding the page.

If your organization uses Material Safety Data Sheets (MSDS), be sure to cite any relevant information on your method sheets to protect your operators. Other safety notices, such as wearing gloves, or warning of hazardous materials should be clearly noted.

Test your method sheets with your operators, they should be able to successfully build a product by following them. Treat these documents as a living document - one that should always be updated and improved. Unless you are using a digital work instruction system, be cautious of operators photocopying the instructions, this can be a major concern with revision control.